In today’s competitive manufacturing landscape, precision and reliability are essential. Tig Welding Services is pivotal in delivering high-quality welds across various American industries, ensuring structural integrity and aesthetic appeal. As businesses seek consistent, dependable results, understanding the fundamentals and benefits of TIG welding becomes crucial for informed decision-making.

What Is TIG Welding and Why Is It Preferred?

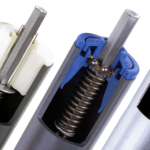

Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a method that uses a non-consumable tungsten electrode to produce a clean, high-quality weld. This process is favored in industries where precision is paramount, such as aerospace, automotive, food processing, and even medical device welding.

Key Advantages of TIG Welding Services:

- Superior Weld Quality: TIG welding allows exceptional control over the weld bead, producing clean and defect-free joints.

- Versatility: It is suitable for a wide range of metals, including stainless steel, aluminum, magnesium, and copper alloys.

- Minimal Spatter: The process generates little to no spatter, reducing the need for post-weld finishing.

- Strong, Reliable Bonds: TIG welding provides robust and durable connections, essential for critical applications.

- Aesthetic Appeal: The precise nature of the process results in visually appealing welds, which are crucial for components where appearance matters.

These attributes make TIG welding indispensable for industries that cannot compromise on quality and reliability.

Applications and Considerations for American Industries

American manufacturers rely on TIG welding for applications demanding both strength and precision. The process is especially valuable in sectors where safety and compliance with strict standards are mandatory.

Common Industrial Applications:

- Aerospace Components: Ensures lightweight, high-strength joints in aircraft and spacecraft.

- Automotive Manufacturing: Used for exhaust systems, chassis, and custom parts requiring precision.

- Food and Beverage Equipment: Provides sanitary welds for stainless steel tanks and piping.

- Medical Device Fabrication: Ensures contaminant-free, strong welds for sensitive devices.

Choosing the Right Tig Welding Services:

When selecting a provider, consider the following:

- Experience and Certification: Skilled technicians with relevant certifications ensure adherence to industry standards.

- Material Compatibility: The provider should have expertise in various metals and alloys.

- Quality Control: Robust inspection procedures guarantee weld integrity and compliance.

- Customization Capability: Ability to handle unique project requirements, from prototypes to high-volume production.

It is essential to partner with professionals who understand the nuances of the process and can deliver tailored solutions for diverse needs.

The Value of Professional TIG Welding

Entrusting your components to a reputable TIG welding service offers several advantages:

- Consistent Results: Advanced equipment and skilled welders deliver repeatable, high-quality outcomes.

- Cost Efficiency: Precision reduces material waste and rework, saving time and resources.

- Enhanced Safety: Properly executed welds ensure compliance with safety standards, reducing liability.

Moreover, TIG welding’s adaptability means it can address specialized requirements, such as those found in medical device welding, where cleanliness and accuracy are non-negotiable.

Tig Welding Services is a cornerstone of American industry, enabling manufacturers to achieve reliable, precise, high-quality welds across various applications. From aerospace to medical devices, the advantages of TIG welding superior strength, versatility, and visual appeal make it the go-to choice for critical projects. For businesses seeking dependable results, partnering with experts like Micro Weld, Inc. ensures that every weld meets the highest standards of quality and performance.